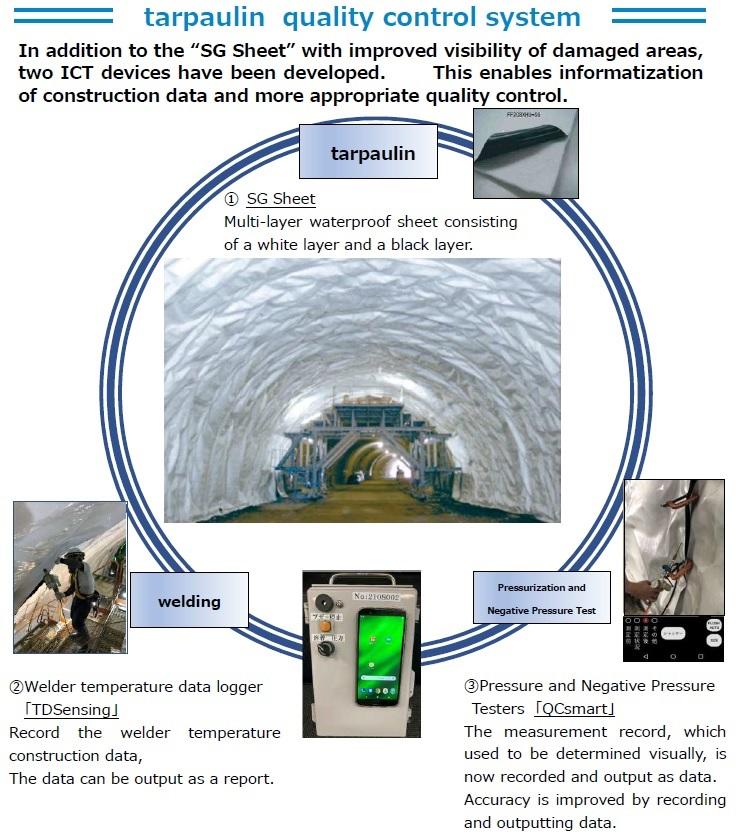

ICT welding machine with visible welding data

TDsensing

Product Description

商品説明

Overview

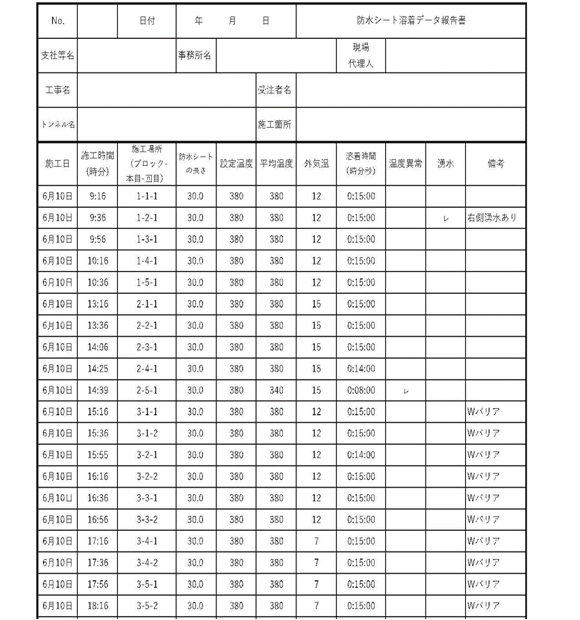

By connecting the welding machine of waterproof sheets for the NATM method to a smartphone, data on welding temperature and installation time can be collected. The collected data can be output in Excel.

The welding temperature is displayed on the smartphone in real time, and a buzzer sounds when the temperature reaches a threshold value, allowing the user to notice potential welding defects during installation, preventing cycle time degradation due to rework and contributing to stable quality.

Features

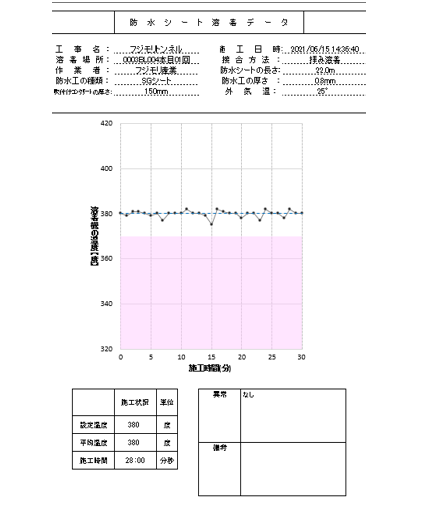

¶ Simple to use

Simply prepare and connect the dedicated welding machine and launch the smartphone application.

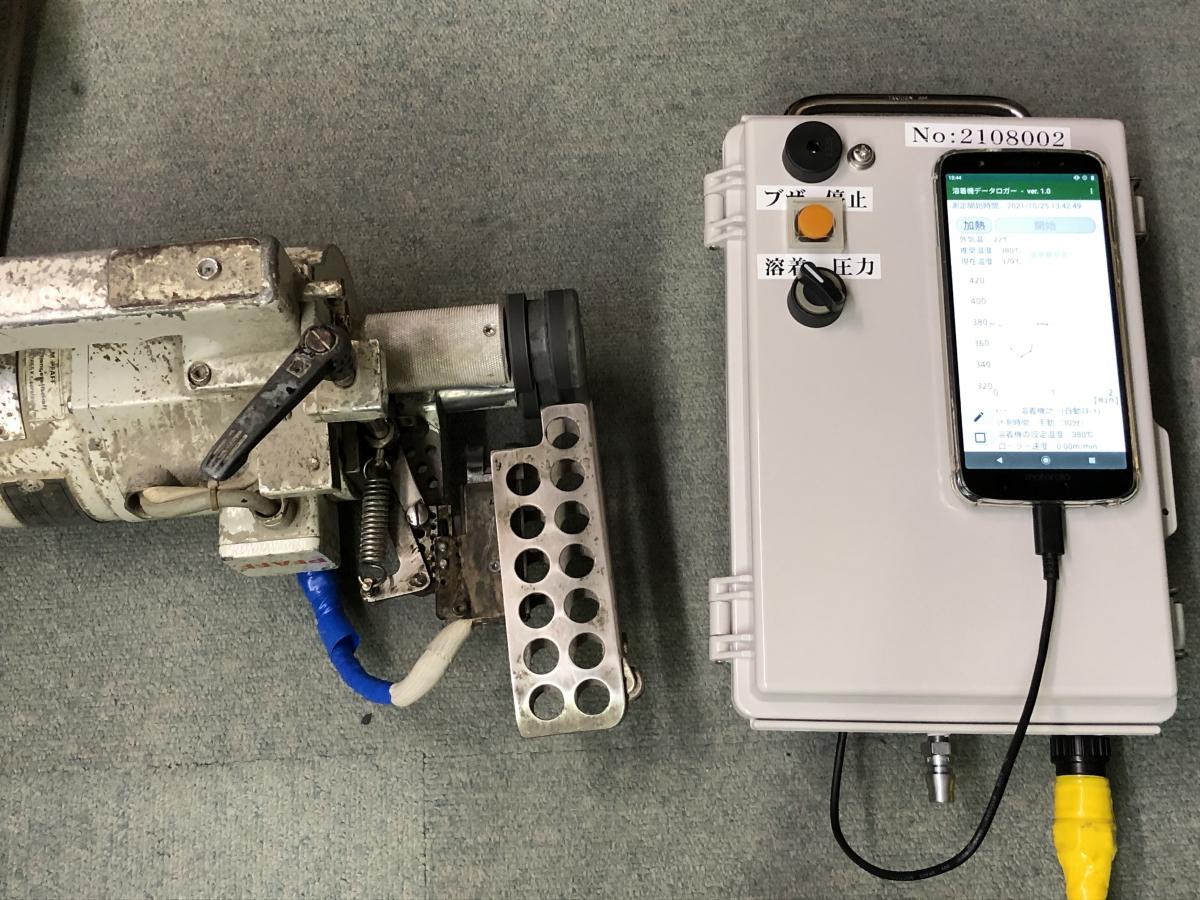

¶ Automatic acquisition of welding data

Data on welding machine temperature and welding time can be automatically acquired and saved, and can be output to CSV data for automatic reporting. By importing multiple data sets, it is also possible to create a tally table of welding data, making it possible to compare data.

¶ Covers for inexperienced workers

The temperature can be set automatically according to the outside temperature, enabling installation that does not depend on the skill level of the workers. The recorded data also supports worker inexperience and contributes to improved construction quality.

¶ Early detection of temperature drops

Temperatures are measured in real time and can be constantly checked on graphs within the application. A buzzer sounds when a temperature drop occurs, enabling early response.

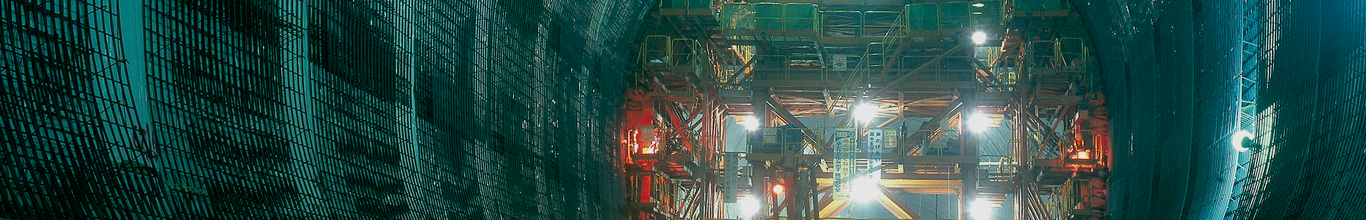

Fujimori's Quality and Productivity Improvement Scheme

Since QCsmart and TDsensing work with the same smartphone and measuring box, their combined use enables integrated management of data from welding to inspection, making a significant contribution to quality control of tarpaulins and improvement of on-site productivity.