The most used waterproofing membrane sheet for tunnel in Japan

SG-sheet

waterproofing membrane sheet for tunnel

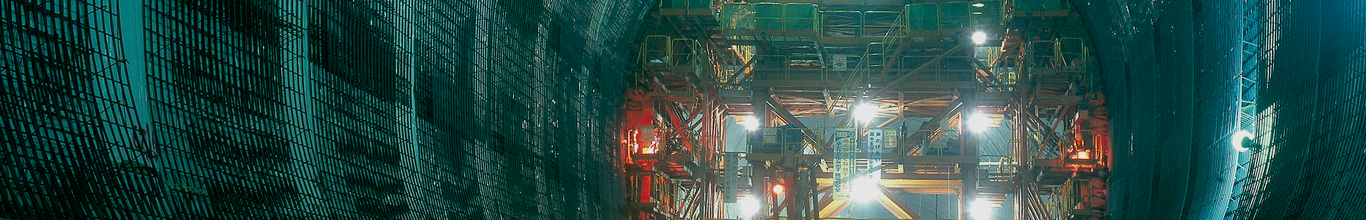

SG-sheet, a waterproofing membrane sheet for tunnels, has been used by many customers in all types of NATM tunnels. Our quality have always been top class in Japan, and among them, SG-sheet has been supported by many customers.

Product Description

商品説明

■features

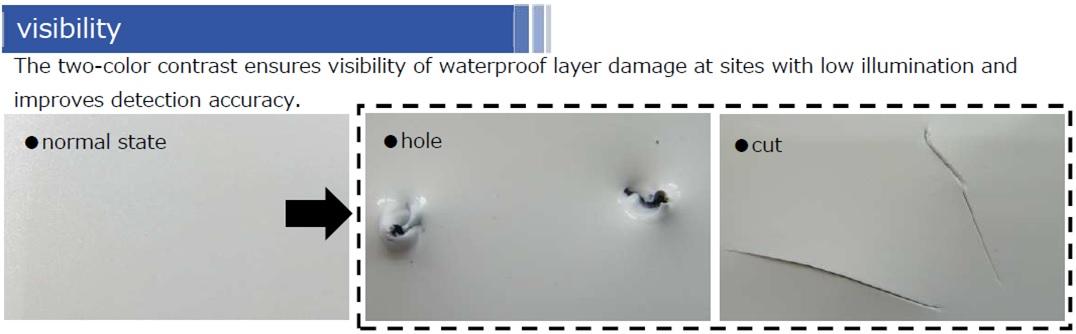

The waterproof layer (sheet) is composed of two layers, a white layer (inner side) and a black layer (ground side), so that if the white layer is damaged, the black layer inside the sheet will appear, allowing the damaged area to be seen and detected. This improves the quality of the waterproof sheet and reduces the risk of water leakage even in tunnel construction environments where it is difficult to distinguish damaged areas. This is more effective in areas where damage is more likely to occur, such as in sections where the lining rebar is easily damaged.

In combination with the “Standard Specifications (FF208XHU-SG),” the “High Drainage Type,” “Wide Separately Attached Type,” and “W-Barrier (double-welded) Type” can be manufactured as a single unit, and their features can be further combined to further enhance waterproof quality.

.

■Standard / Shape

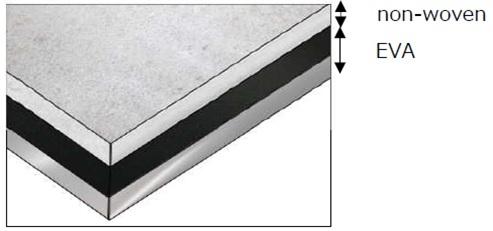

¶ Material

EVA is the main material, and conforms to the waterproofing sheet standards of each ordering party.

¶ Standards

The waterproofing layer is manufactured and sold according to the standard specifications for standard areas and for cold climates.

The permeable layer is made of long-fiber non-woven fabric and can be changed according to the ground conditions. In sites with high groundwater inflow, a high drainage type permeable layer can be used to reduce the water pressure on the backside of the lining.

.

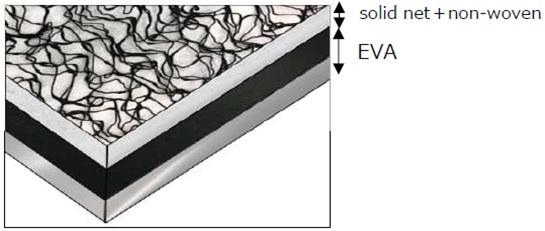

High drainage type (PHU type)

The three-layered structure of the waterproof sheet, with a three-dimensional mesh laminated to the back of the permeable layer, makes it possible to be used in tunnels with large water inflow. The drainage capacity is 40 times higher than that of the standard permeable layer, and the structure can withstand the pressure of concrete placement.