Following/Automatic/ICT and

i-Construction/Remote and

Realtime - system

fair-system

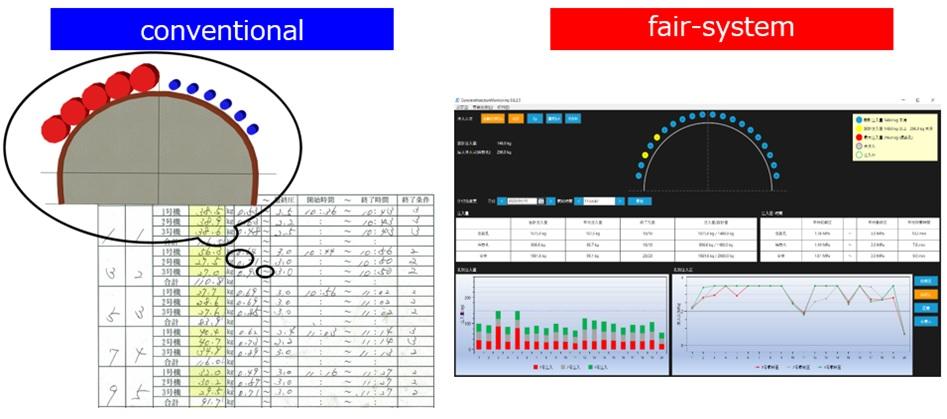

Injection system “fair-system®” for tunnel auxiliary construction method

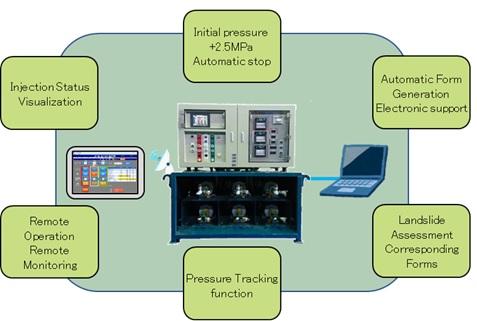

The system will be networked with injectors to enable injection operation, monitoring, and report generation.

Product Description

商品説明

System Overview

Based on our many years of experience, we have developed an injector that can improve quality and productivity by unraveling the injection process. Auto-automatic control, data collection and management will make a smart change at the injection site.

.

Easy and effective injection

¶ Auto-Reporting

Automatic report generation based on collected data. Reports are generated quickly, accurately, and in a format that captures information easily.

¶ Automatic Reporting Box Output

Automatic reports can be exported to Box, a synchronous storage service on the Internet. You can view the report data in the form of a web page. Please contact us for more details.

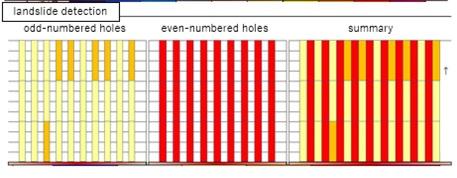

¶ Ground evaluation type form

By displaying the injection data from a bird's eye view, it is possible to grasp the injection situation more intuitively. By estimating the ground condition in advance, it is useful for avoiding hazards such as avalanche.

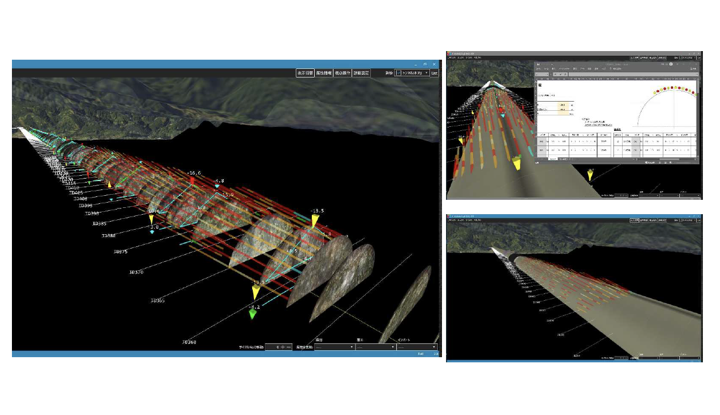

¶ CIM of injection data

By importing the injection data into “E-G Modeling” of Calculation Studio, it is possible to convert the data into CIM. If drilling data is imported, the two data can be complemented. Only when “E-G Modeling” is used.

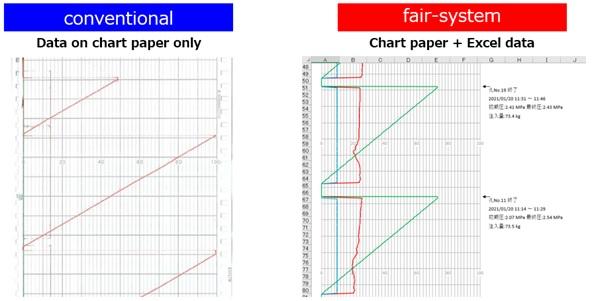

¶ Chart data digitization

Chart data can be exported to Excel. Since it is electronic data, it is easy to see and to use the data effectively.

.

Reliable injection

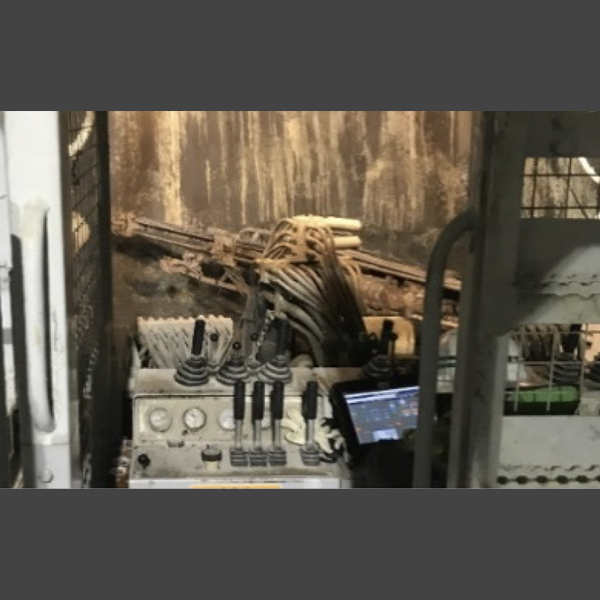

¶ Visualization of injection status

Enables real-time monitoring via tablet or laptop PC. This is useful for flexible response, such as changing to the appropriate injection volume.

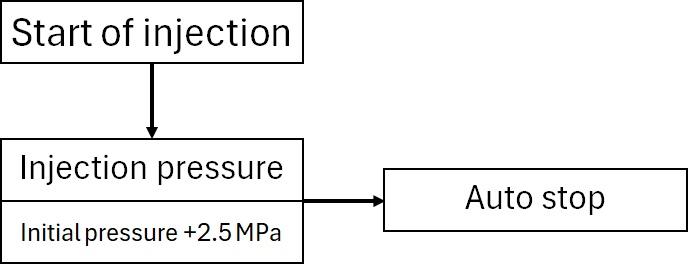

¶ Automatic shutdown of initial pressure +2.5 MPa

Automatic shutdown in case of a sudden increase in injection pressure. Supports safe injection management in accordance with the rules.

.

Power-saving and safe injection

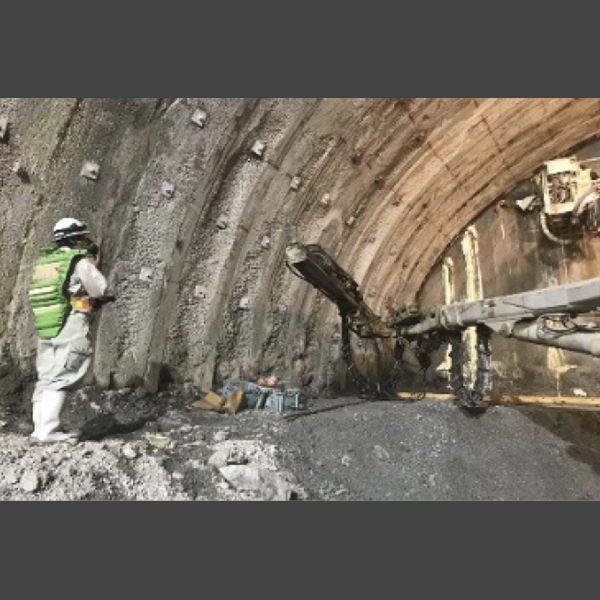

¶ Remote operation

The system can be remotely operated with a tablet using the wireless LAN facility installed in the injection car. This allows the operator to monitor the cut and perform the injection operation, contributing to the reliability and safety of the construction process.

¶ Remote monitoring

A management PC can be installed at the wellhead to check the injection status even in the suburbs.

¶ The details of the system vary depending on the network environment and Internet connection in the well.

.

Safe injection

¶ System operation check

Output of operation check forms that can be used to verify data integrity.

¶ Error prevention function

The system is equipped with an error prevention function as a standard feature.