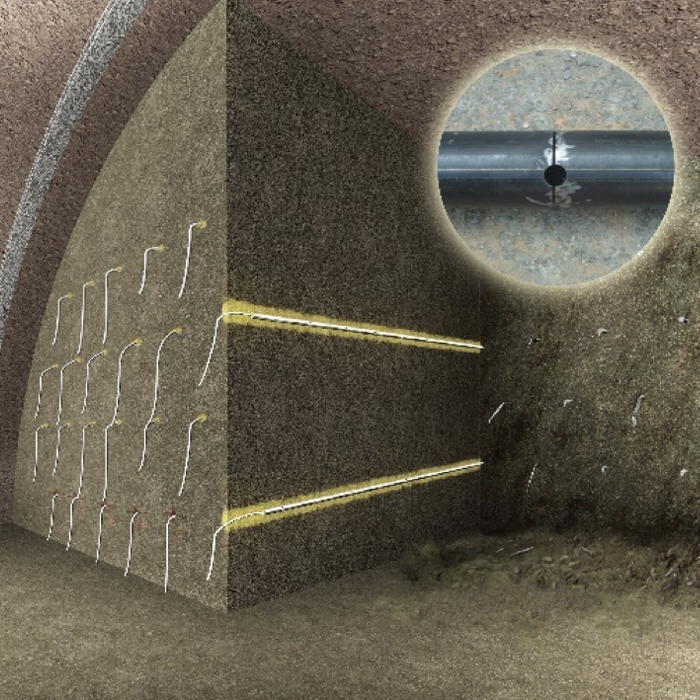

Suppresses extrusion and loosening of the ground at the tunnel face

F-S bolt method (face bolt)

The F-S bolt method is a method of reinforcing and stabilizing ground during mountain (NATM) tunnel excavation. The F-S bolt method stabilizes the excavation surface by preventing extrusion and loosening of the face section through the installation of face bolts. Two types of face bolts are available: the long steel pipe type F-S bolt method and the short GFRP bolt method.

Product Description

商品説明

■face Bolt Overview

The F-S bolting method involves placing multiple long steel pipes on a surface. Slits are made in necessary areas along the entire length of the steel pipe to facilitate cutting and removal of bolts as excavation progresses. High tensile and shear resistance can be expected with the use of steel pipes.

The GFRP bolt is a post-insertion method of short bolts made of resin. It is utilized not only for surfaces, but also when chemical injection is required in areas to be excavated later, such as widening and advanced conduits.

■F-S Bolt Method Features

¶ Improved workability

The use of steel pipes and special slitting process facilitates casting, cutting, and removal, and also makes it easy to separate removed parts that go into the excavation sled.

¶ High rigidity

High shear strength compared to resin pipes, which can be expected to provide shear resistance in addition to tensile resistance against face extrusion.

¶ Wide applicability

Casting can be done in ultra-long lengths (40m or less) according to the needs of the site. Urethane, cement, mortar, etc. can be combined as injection materials.

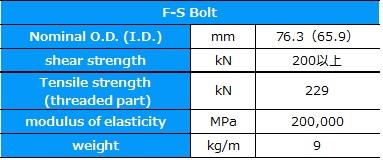

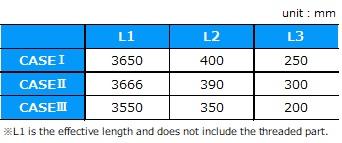

■standard

.

F-S Bolt Method

The F-S Bolt is an injection-type long steel pipe mirror bolt that has been used for mirror reinforcement in collapsible ground with low self-support. Injection materials can be selected from urethane, cement, and mortar.

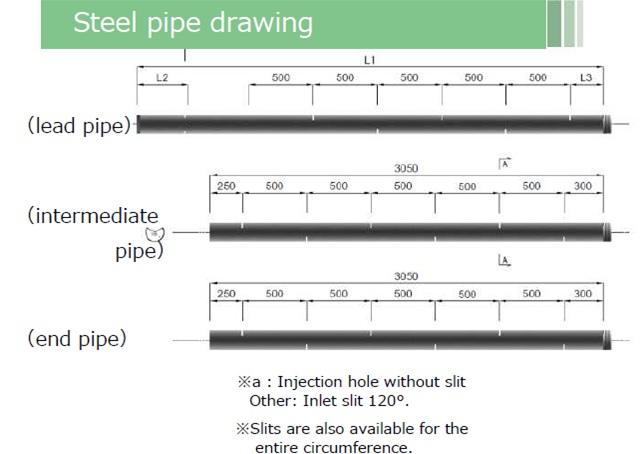

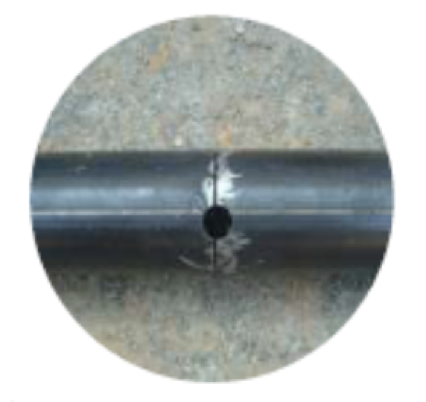

◆Processing/Shape

The standard type has a slit pitch of 500 mm and a slit opening of 120°. The slit opening is 120°. It is easy to cut during excavation and provides excellent workability. The pitch and slit process (all-round slit) can be changed to suit the ground and site conditions.

◆High adhesion strength

The pullout test after casting shows that the pullout capacity is more than 200KN against soil-like ground, and it has the function as a mirror bolt. In addition, the stress change of the F-S bolt due to excavation is measured by axial force, and it is confirmed that the function is retained even after cutting during excavation.

◆Support for extra-long lengths

The standard type has an effective length of 12.5 m, but it is possible to install extra-long bolts depending on the site conditions. We have experience in construction up to about 40m. We will consider special designs in consideration of construction, ground conditions, and the combination of injected materials.

GFRP Bolt

Short post-insertion type high-strength FRP bolts. They are used when the hole wall is expected to be self-supporting due to drilling, and the main purpose is to improve the ground at the face by using chemicals. The bolts are lightweight and have high extraction strength, so they are often used for partial improvement.